How is AutoCAD used for repairs and maintenance?

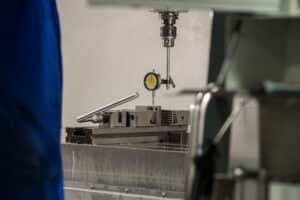

Are you tired of spending more on parts, repairs and replacements than you budgeted this year? Look no further than AutoCAD services for your manufacturing needs! How much do you know about the power of AutoCAD in design, manufacturing, and CNC machine-based repairs?